Unleashing the Beast – Engineering Marvels Behind Diesel Engines

Diesel engines, often associated with rugged reliability and fuel efficiency, have undergone a remarkable evolution. Modern high-performance diesel engines, often referred to as engineering marvels, represent the culmination of decades of advancements in thermodynamics, materials science, and precision engineering. These powerhouses drive some of the world’s most demanding applications, from commercial trucks and construction machinery to high-performance sports cars and marine vessels. Behind the seemingly simple operation of these engines lies a sophisticated array of technologies and design principles that enable them to produce enormous power while maintaining efficiency and durability. At the heart of every diesel engine is its combustion process, which differs significantly from gasoline engines. Diesel engines rely on compression ignition, where air is compressed to extremely high pressures and temperatures before fuel is injected. The fuel ignites spontaneously upon contact with the hot air, leading to efficient and powerful combustion. One of the key engineering challenges is optimizing this combustion process to maximize power while minimizing emissions, noise, and fuel consumption.

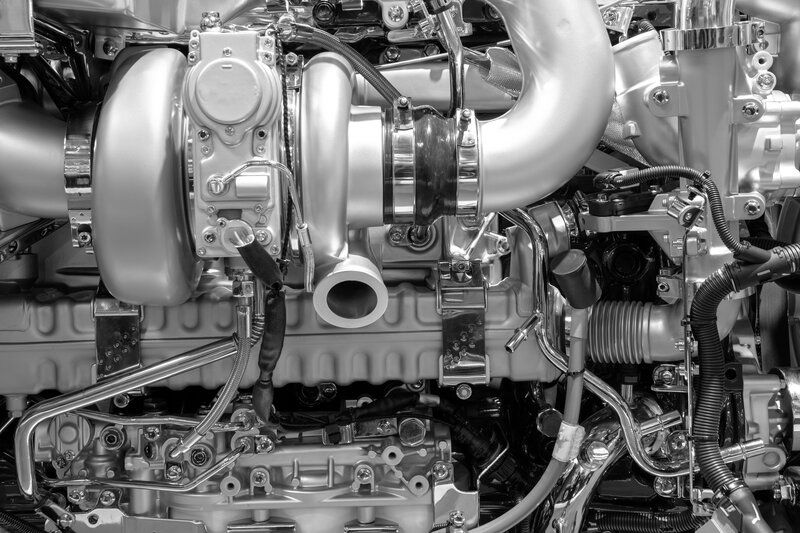

Modern engines use direct fuel injection, often with multiple injection events per cycle, to precisely control how and when the fuel burns. This fine-tuned injection system is critical for enhancing performance while reducing the pollutants traditionally associated with diesel combustion, such as nitrogen oxides NOx and particulate matter. A major factor in the efficiency of high-performance diesel engines is turbocharging. Turbochargers force more air into the combustion chamber, allowing for a greater volume of fuel to burn more efficiently, which significantly boosts power without drastically increasing engine size. Advanced variable geometry turbochargers VGTs can adjust the angle of the turbine blades to optimize performance across a range of engine speeds, ensuring both low-end torque and high-end power. Paired with intercoolers, which reduce the temperature of the compressed air, turbocharging contributes significantly to both performance and fuel economy in diesel engines. Another critical innovation in modern diesel engines is exhaust gas recirculation EGR and selective catalytic reduction SCR.

These systems are designed to tackle emissions, which have long been a concern for diesel technology. EGR reduces the formation of nitrogen oxides by recirculating a portion of the engine’s exhaust gases back into the combustion chamber, lowering the combustion temperature. SCR, on the other hand, treats exhaust gases by injecting a urea-based solution, commonly known as DEF Diesel Exhaust Fluid, into the exhaust stream. This chemical process converts harmful nitrogen oxides into harmless nitrogen and water vapor, allowing high-performance best diesel engine to meet stringent environmental regulations without sacrificing power. Diesel engines are subject to immense pressures and temperatures, requiring components that can withstand such extreme conditions. Advances in metallurgy have led to the development of high-strength alloys for engine blocks, pistons, and crankshafts that resist wear and thermal fatigue. Additionally, modern engines are engineered with tighter tolerances and sophisticated computer controls that monitor and adjust various parameters in real-time to optimize performance and longevity. The integration of electronic control units ECUs has been another game-changer.